SERVICES

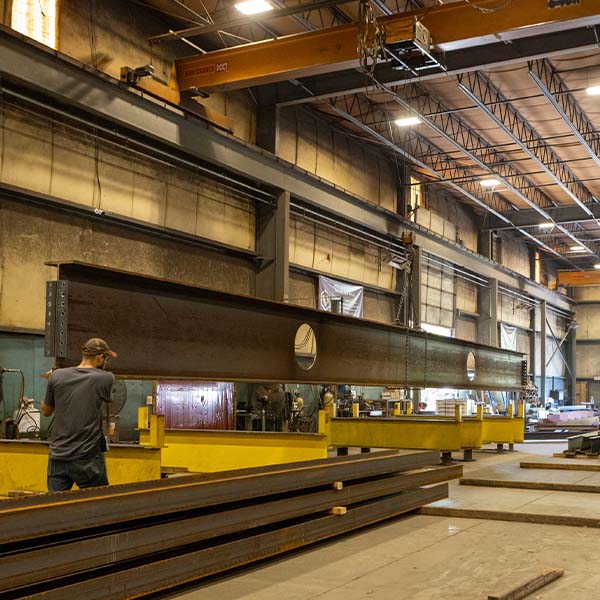

Fabrication

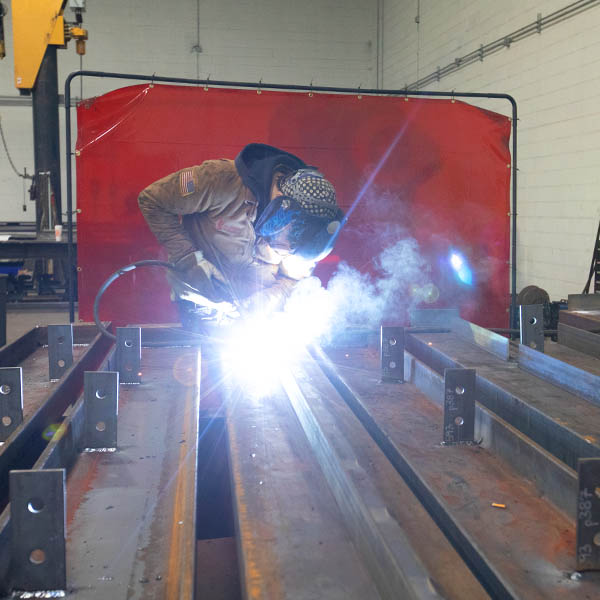

Our 40,000 sq ft fully automated fabrication shop runs 6 days a week with 2 shifts. Our talent staff of stair and railing fabricators can skillfully fabricate everything from OSHA safety railing and grating platforms to elaborate monumental and feature stairs.

Equipment List:

- (2) 3 Ton Overhead Cranes

- CNC 200 Amp Lincoln Python X Plasma beam processing

- CNC 5x5 Peddinghaus Angle Line

- CNC 200 Amp 5x10 Plasma Table

- CNC 40” Beam Drill Line

- CNC 8’ x 30’ ALT Railing Layout Machine

- CNC Mandrel Tube Bender

- CNC Pipe Plasma Cutter

- 120 Ton Press Brake

- 60 Ton Ironworker

- 36” Plate Polisher

- (2) 20” Bandsaws

- (2) 14” Cold Saws

- (20) 300 Amp Multi-process Welding Machines (GTAW, SMAW, GMAW)

- (3) 48’ Flatbed Trailers

- (2) Class 8 Semi Truck Tractors

- (3) 10k Forklifts

Robotics and Automation

All material processing is fully automated, increasing accuracy, quality, and production.

Layout of stairs, railings, and structural members is performed automatically with robotics to which allows our workforce to focus on assembly and welding.

Logistics

Each assembly is quality checked before coating and shipping to ensure standards are met before reaching the site.

CNC machinery is calibrated and rechecked routinely to ensure accuracy is kept to the highest standard.

Shipping

With our own fleet of trucks, we can control our delivery schedules and meet material needs onsite.

Our friendly dispatch team can advise clients with live delivery status information and requests

Quality Assurance

Our team tracks all material through the production process through a steel specific program ensuring assemblies are delivered to the site complete.

Detailed reports are distributed weekly, keeping management and production staff up to date with vital information.

Miscellaneous

Our talent staff of stair and railing fabricators can skillfully fabricate everything from OSHA safety railing and grating platforms to elaborate monumental and feature stairs. With all member processing and layout fully automated, we provide excellent accuracy and quality in a time effective manner.

Ornamental

Our ornamental division operates in a specialized and separate bay within the shop to isolate and protect nonferrous metals and glass from steel contamination. Skilled craftsmen in this division focus on scope items that require a special eye for details and craftsmanship. CNC machinery in conjunction with skilled trade equates to artistically fabricated products with cost and schedule benefits.

Structural

With state-of-the-art comprehensive CNC processing machinery members are cut, coped, dilled, marked, and laid out in one step increasing shop productivity and accuracy.